LABORATORY

LABORATORY

We check the density, the apparent specific weight and the particle size analysis on both Granulated and Rubber Powder products.

One batch every 4 hours of production is tested by sampling according to UNI EN 932-1.

Examined in the laboratory for visual impurities it is introduced into a special dmc container according to the directives of the UNI EN ISO 17828: 2016 standard to obtain the apparent density of the granules and rubber powders.

The use of a REITCH particle size analyzer allows us to check the distribution curve.

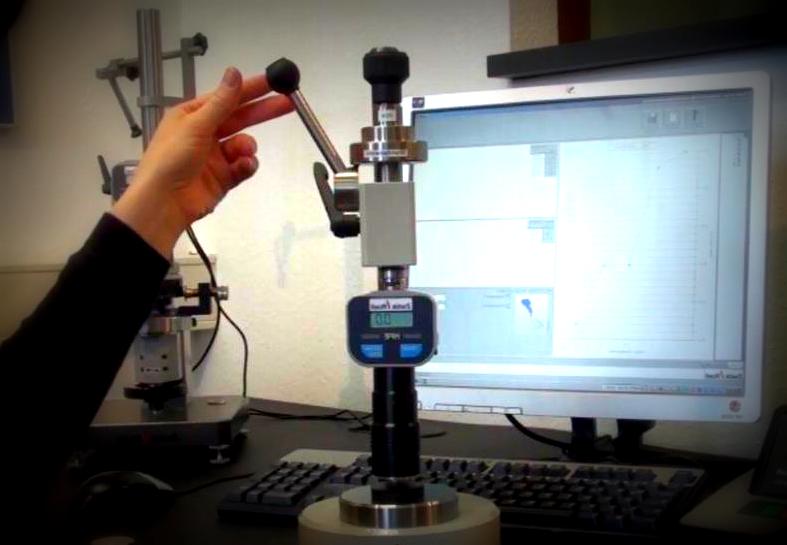

Through hardness testers we carry out hardness tests on materials that are transferred to the source.

Although the data are already declared by the manufacturer, the test allows us to also perceive the post-aging hardening of the material.

The Standard to which we refer specifically is the UNI ISO 48-4:2019.

The colorimetric control is carried out on the production obtained and specifically on the granulates. It is very useful in maintaining high performance between production batches of colored rubber granules. However, we always recommend the use of an entire batch of our production on the drafting of a playground, in order to avoid chromatic differences which, even if the slightest change can compromise the result.