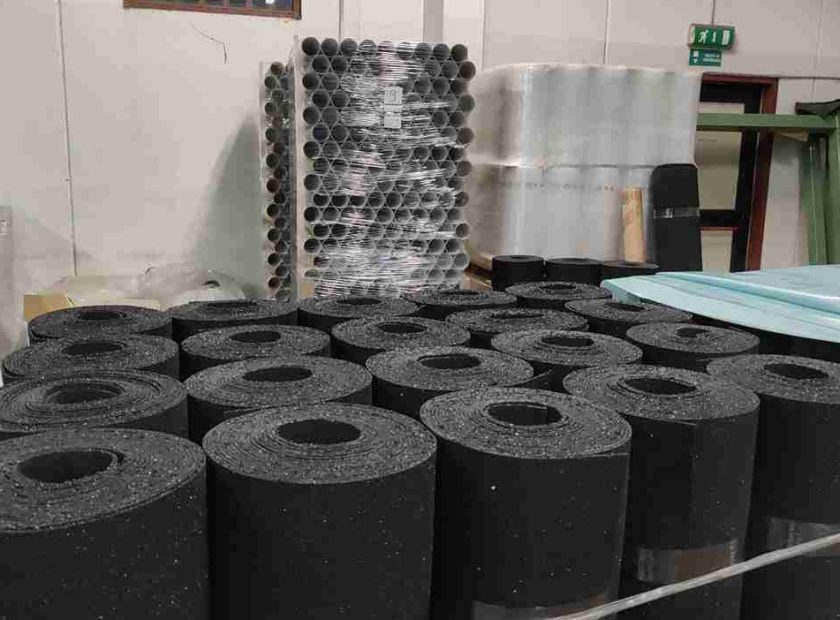

From Recycled Granules to Acoustic Rolls: A Sustainable Journey

Transforming end-of-life tires into rubber rolls for acoustic insulation exemplifies a successful circular economy model. Through granulation and agglomeration processes, recycled rubber granules become high-performance materials for noise reduction in residential and industrial buildings.

These rolls offer excellent sound-absorbing properties, enhancing acoustic comfort and reducing environmental impact. Learn more at [soundproof-rubber-rolls.com]

These rolls offer excellent sound-absorbing properties, enhancing acoustic comfort and reducing environmental impact. Learn more at [soundproof-rubber-rolls.com]